Re-grinding of:

End Mills, standard Drills and special Drill points, Hole Cuttes, Centering tip Drills, taper End Mills.

HSS and carbide Slitting Saws, HSS Cutt-Off Saws, HSS cold Saw blades, Rotary Knives, Solid carbide Cutters and HSS Cutters.

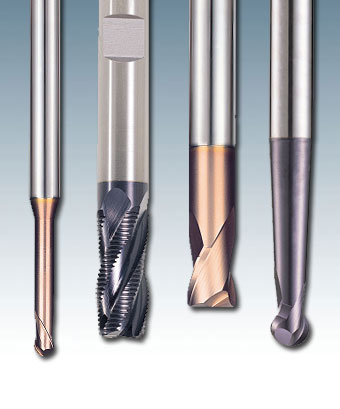

Type of end mills

Square End, Corner Chamfer, Corner Radius, Ball nose, Straight flutes, Spireal flutes with right hand cut and right hand helix end mills are easily regrind

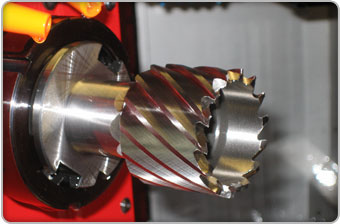

Grinding operations:

-

O.D. flat or eccentric relief

-

Gashing Standard or high speed gash, plunge or walking gash. Gash depth autocalculate

-

Notching plunge or walking notch

-

End Face Center cutting, over the center and non center cutting end mills

-

Ball Nose with radial relief, flat with continuous path on ball and O.D. or with eccentric relief in two separate grinding cycles.

-

Flute polishing

-

Flute from the solid material with main and several blended cuts.

Ball nose cutters diameter from 5.00 to 52.00 mm

| HSS and HM | |

| 2 cutters | |

| 4 cutters | |

| Different corner radius |

Cutters with a flat front surface diameter from 5.00 to 52.00 mm

| HSS and HM | |

| 2 cutters | |

| 3 cutters | |

| 4 cutters | |

| 6 cutters | |

| 8 cutters | |

| 10 cutters |

Drills

Standard drills and special drill points, step and subland Drills with helical flutes right and hand cutting / right hand helix, 2 or 3 flutes.

Standard Drills:

- Conical relief

- Web thinning

Special drills:

- Split point

- 3 Facets

- Straight chisel angle, Straight+S shape or S shape only, Aviac type and others.

Hole cutters

As a part of continuous development of grinding, the latest addition is the Hole Cutters Grinding.

Hole Cutters are designed for use on magnetic drills bases, drill presses and milling machines in applications ranging from steel erection and fabrication and bridge and highway maintenance to truck and trailer manufacturing and elevator repair. Designed for fast, efficient hole making in engineering and structural steels. Universal cutters cut only the material necessary to produce a quality hole the rest pops out as a slug. Advantages are a better finish, longer tool life, faster hole production, and closer tolerances.

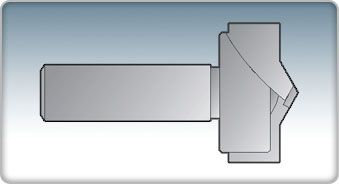

Developed for regrinding of carbide inserts Centering Tip Drills, sharpen the end face and gash in the centering point.

The tool is design in two pieces (steel body and Carbide tip insert brazed on the steel body).Standard geometry combines highly efficient, stable, cutting action to minimize power consumption.

- CUT OFF high speed steel saw blades

- Slitting saws, pipe cutting saw blades

- Rotary knives, paper slitting knives; HSS paper cutting knife

- TCT circular saws and cermet tipped saws

-

Hot and friction saw blades for metal cutting

CUT OFF high speed steel saw blades

KINPOL Re-grind HSS circular sawblades in diameters varying up to 720 mm in various designs. The tooth forms most used are HZ, BW, B, AW, A, VP and 'Chipbreaker' . Grinding is based on DIN standards 1836, 1837, 1838 and 1840.

Slitting saws, pipe cutting saw blades

Slitting saws in both high speed and super high speed steels suitable for cutting-off, milling, and grooving steels and alloys on manual, semi-automatic and fully automatic machines. The saw blade range is o 20 mm - o 315 mm with thicknesses ranging 0,2 mm - 6 mm in variable increments with tooth forms: A - B - BW.

Hot and friction saw blades for metal cutting

Friction saw blades are used for cutting of steel tubes and profiles by low working temperature, it means by material temperature up to 250°C. They are made from chrom-vanadium steel marked and they are heat-treated to reach the optimum ratio of tenacity and hardness, which is suitable for cutting of material with high circumferential cutting speed.

Engraving Tools are made of solid carbide and are sharpened on 1-end for right hand cut.

They work very well engraving harder materials such as steel and stainless steel and can also be used for engraving materials such as aluminum, brass, copper, plastic and more. The conical shape included angles of 60° tools are available with flat tip widths from 0.1 - 1 mm to produce engraving lines of increasing width. A 0.1 tip will produce a very fine engraving that is equivalent to sharp point engraving tools that do not have a flat tip width on the end.