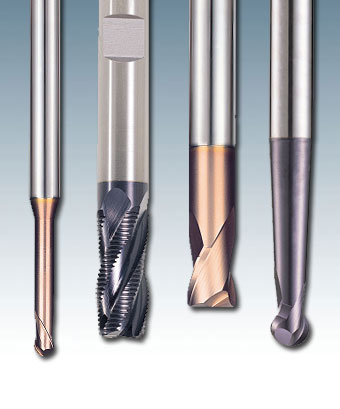

Frezy z powierzchnią czołową kulistą HM

Frezy z powierzchnią czołową płaską HM, HSS

Frezy węgliwkowe, frezy węglikowe wykańczające, frezy węglkowe zgrubne, frezy ze zmienną geometrią, frezy z promieniem naroża, frezy HSS

Frezy z powierzchnią czołową kulistą

o średnicy od 5.00 do 52.00 mm

| HSS oraz HM | |

| 2 ostrzowe | |

| 4 ostrzowe | |

| Różne promienie narożne |

Frezy z powierzchnią czołową płaską

o średnicy od 5.00 do 52.00 mm

| HSS oraz HM | |

| 2 ostrzowe | |

| 3 ostrzowe | |

| 4 ostrzowe | |

| 6 ostrzowe | |

| 8 ostrzowe | |

| 10 ostrzowe |

| przykładowe narzędzia: | ||

|

|

|

|

Multi cutter Updown |

Updown |

Frezy z powierzchnią czołową płaską HM, HSS

Cylinder

Taper

Angular Cutter

Plan Face

Chamfer

Corner Radius

Ball Nose

Circular Arc

Double Radius

2 at Center 1 above Center

Centring Point Regulare

Rising helix of fluting

Falling helix of fluting

wavecut

Workpiece: |

|

| - | Cylinder |

| - | Taper |

| - | Angular Cutter |

Point: |

|

| - | Plan Face |

| - | Chamfer |

| - | Corner Radius |

| - | Ball Nose |

| - | Circular Arc |

| - | Double Radius |

Geometry: |

|

| - | Regulare |

| - | 2 at Center |

| - | 1 above Center |

| - | Centring Point |

| - | 3 at Center |

Cutting Edge Combination: |

|

| - | right helix/right cutting |

| - | left helix/left cutting |

| - | right helix/left cutting |

| - | left helix/right cutting |

Division: |

|

| - | Equal / unequal division of teeth |

Production / Regrinding: |

|

| - | Production by different infeed (several steps) |

| - | Regrinding with calculation of removal length, periphery and rake. |

| - | Regrinding, finishing with different wheels |

Preparation: |

|

| - | Separating |

| - | Profile roughing |

| - | Profile finishing |

Main Fluting |

|

| - | Meas. definition: Point-/ normal cut |

| - | Grind direction: Forward / backward |

| - | Optional spark out grinding |

Taper: |

|

| - | Constant angle / constant helix |

| - | Regrinding with undefined helix |

Periphery |

|

| - | Linear relief: 1st/ 2nd /3rd relief angle |

| - | Radial relief: Cross-/ longitudinal |

Roughing: |

|

| - | Grind direction: Forward / backward |

| - | Optional spark out grinding |

Heel |

|

| - | Grind procedure: Crosswise-/ longitudinal |

| - | Production by different infeed (several steps) |

| - | Grind direction: Forward / backward |

| - | Optional spark out grinding |

End Face: |

|

| - | Linear relief grinding |

| - | Hollow grinding |

Chamfer Clearance/Chamfer: |

|

| - | Linear relief: 1st/ 2nd /3rd relief angle |

| - | Grind. direction: Forward / backward |

| - | Optional spark out grinding |

Gashing: |

|

| - | Grinding procedure |

| - | Recessing / Interpolation |

| - | Radius at entry and exit |

| - | Variable aperture angle |

Notching: |

|

| - | Radius at entry and exit |

| - | Variable entry- and aperture angle |

Profile Simulation: |

|

| - | Simulation of intersection at all operations |

| - | Wheel/workpiece-simulation |

| - | Machining simulation |

Shank |

|

| - | Reducing the shank diameter Clamping area |

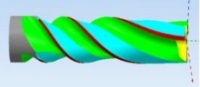

1.2 Ball |

|

|

|

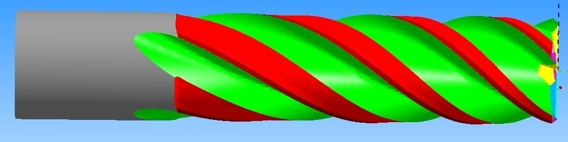

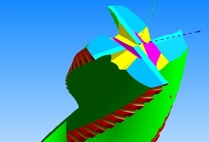

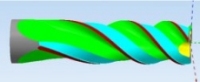

1.3 Variably Helix |

|

|

|

Variably Helix of Fluting: |

|

| - | Cylindrical and tapered tools |

| - | Front and rear angle of helix |

| - | 3 sections: Constant angle within 1. and 3. section; transition between front and rear |

| - | helix-angle within 3. section |

| - | Rising or falling helix |

| - | |

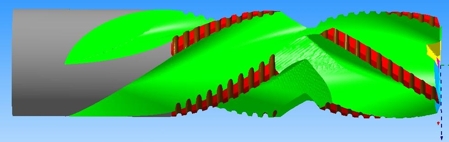

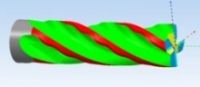

1.4 Wavecut |

|

|

|

Wavecut: |

|

| - | Cylindrical tools |

| - | Roughing cutting corresponding to a sinusoidal cutting edge along the helix |

| - | Period and amplitude of wave according to sinus-function |

| - | Starting point offset at every tooth |

| - | Orientation of wave to the tool-center or to the cutting edge |