| Technical Specification |

||||

|

4 AXES TOOLS GRINDING MACHINE |

|||

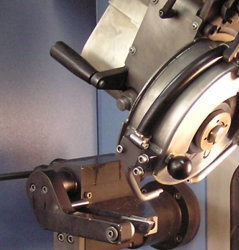

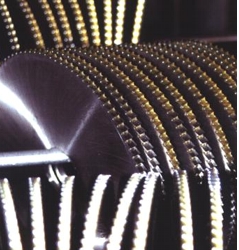

High-Tech-Solution for re-sharpening, re-toothing and chamfering of HSS metal cutting circular saw blades. Machine is the ideal machine for the fully automatic complete processing of metal circular saw blades. In addition to a high degree of automation, the machine provides outstanding grinding quality as well as low grinding and secondary times.

|

||||

|

||||

Type of Re-grinded tools: |

||||

|

CUT OFF high speed steel saw blades |

|||

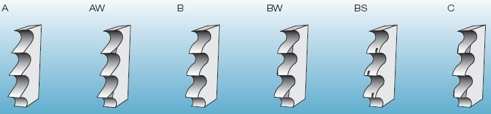

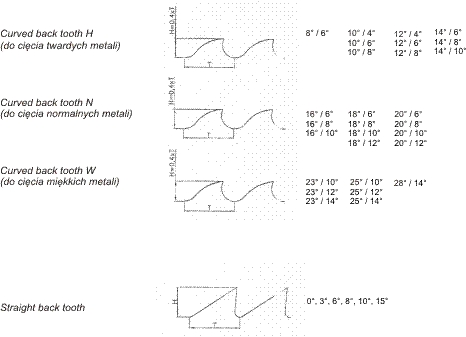

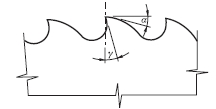

The tooth forms most used are HZ, BW, B, AW, A, VP and 'Chipbreaker' . Grinding is based on DIN standards 1836, 1837, 1838 and 1840. |

||||

|

CUT OFF high speed steel saw blades |

|||

The tooth forms most used are HZ, BW, B, AW, A, VP and 'Chipbreaker' . Grinding is based on DIN standards 1836, 1837, 1838 and 1840.

|

||||

|

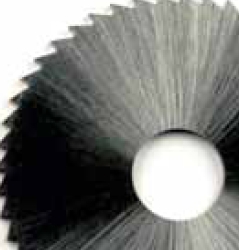

Slitting saws, pipe cutting saw blades |

|||

Slitting saws in both high speed and super high speed steels suitable for cutting-off, milling, and grooving steels and alloys on manual, semi-automatic and fully automatic machines. The saw blade range is o 20 mm - o 315 mm with thicknesses ranging 0,2 mm - 6 mm in variable increments with tooth forms: A - B - BW.

|

||||

|

Hot and friction saw blades for metal cutting |

|||

Friction saw blades are used for cutting of steel tubes and profiles by low working temperature, it means by material temperature up to 250°C. They are made from chrom-vanadium steel marked and they are heat-treated to reach the optimum ratio of tenacity and hardness, which is suitable for cutting of material with high circumferential cutting speed. |

||||